ACMEFIL ENGINEERING SYSTEMS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ACMEFIL ENGINEERING SYSTEMS P.LTD.

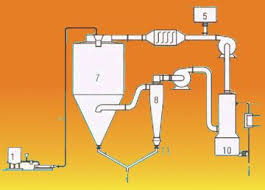

Fluidized Spray Dryer

Single stage spray dryers offer particle sizes of dried material from 50-250 microns. For producing large particles Fluidized Spray Dryers are employed. The atomization of the feed solution is done to produce large droplets and the drying in the first stage is done keeping the moisture content of the powder relatively high. The moist powder is dried in the integrated fluid bed system at the bottom of the drying chamber using hit air, and in the process, agglomeration of fines to larger particles takes place. The absolute fines are carried with the exhaust air leaving the drying chamber to be collected in the cyclone and further recalculated to the drying chamber. Tertiary drying systems comprise of employing additional external drying system to further increase the particle size. Shown in the layout is one of such system incorporating a fluidized spray dryer with vibratory fluid bed drier.

Closed Loop Spray Dryer

These are dryers used for drying the product in solvent base, by spraying the solution or slurries in a nitrogen atmosphere and recovering both the product and the solvent. The drying system can be equipped with fire detection, extinguishing and explosion suppressants. Such systems are ideal for handling solvents, heat sensitive products, prevent oxidation of dried product, and also provide aseptic condition.

Spin Flash Dryers

A spin flash dryer produces powder from feed, which is viscous or gelatinous in nature, paste or filter cake. The two step process involves disintegration of the feed and drying of the disintegrated feed. Depending upon the nature of the feed material, conventional arm design could be used for crystalline, non-sticky material or Acmefil's specially engineered rotating spin design disintegrator could be used to handle sticky and gelatinous materials.

Flash Dryers

Drying process is accomplished by contacting the powder with hot air travelling at high velocity. The heat is used for drying and the air pneumatically conveys the powder for separation in a cyclone or a bag filter. A product classifier ensures only dry powder leaving the drying chamber.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.